On the second page of the Wizard, check the Tab and the Space delimiter boxes. On the first page of the Text to Columns Wizard, we want to select Delimited, if it isn’t already selected by default. Highlight Column A in Excel, click on Data, and select Text to Columns. You will notice that both X and Y coordinates have been copied into a single column, so in order to make them usable we need to separate them into individual columns. Open up Microsoft Excel and copy/paste them into the first cell. The raw coordinates need cleaning up a little before we can import them into SOLIDWORKS. Note, the AirfoilTools site has a nice visualization tool that shows you how the shape of the aerofoil geometry changes as you modify the NACA parameters, which is great if you want to know exactly what those NACA numbers mean. You can copy the NACA 4415 aerofoil coordinates from the University of Illinois at Urbana-Champagne aerofoil database website, or you can obtain it from the AirfoilTools website here. This is relatively straightforward, as there is a wealth of aerofoil coordinate data libraries online, and we can import those coordinates into SOLIDWORKS by using the Curve Through XYZ function.įor this tutorial, we will be using a NACA 4415 aerofoil.

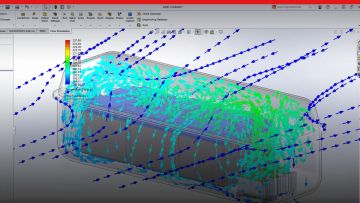

Aerofoil Modellingīefore we can start simulating however, we need to design our aerofoil. To find out more about SOLIDWORKS Flow Simulation 2021,Ĭall us on 01223 200690 or send us a message below.In this tutorial, we are going to be taking a look at running flow visualization simulations on a basic aerofoil (or “airfoil”), which will hopefully be of use to those of you in aerospace engineering courses-or maybe you just like designing RC aircraft and want to simulate your wings before chopping up a load of balsa wood. Just set up the items in the Engineering Database once and they’re ready to use for your past, current and future projects. The Magnus formula for calculating Dew Point Temperature is a great example of when to use this new functionality.

#How to solidworks flow simulation manual#

To further reduce your amount of manual calculations in Flow Simulation 2021, ‘Custom Visualization Parameters’ can now depend on other ‘Custom Visualization Parameters’. For example, you can easily discover the maximum temperature across all of the batteries and PCBs with minimal setup work. Another improvement with Goals is the ability to calculate the minimum, average, and maximum from a selection of goals. When you click the automatic plot min and max options, they are now calculated from this cropped region so you can clearly communicate the range of values without further manual modifications. In SOLIDWORKS Flow Simulation 2021, investigating specific areas of the model can be done by creating a cropped region. A new option in this plot groups all items by type so you can quickly check the energy balance of the simulation and ensure that your study has fully converged. The enclosure itself is designed to act as a heat sink, but how can you determine exactly how the heat is moving from one place to another? The ‘Flux Plot’ provides a graphical interface where you can easily understand where heat is coming from, and where it’s going. This vehicle enclosure has multiple electrical components inside that generate heat. Now you’re ready to create your various custom plots in any other project with only one command.Īnother common application for SOLIDWORKS Flow Simulation is heat transfer. In SOLIDWORKS Flow Simulation 2021, if you create one or more plots you want to use in other projects, simply show the desired plots and choose the new ‘Create Scene Template’ option. You can even create the same plots in multiple projects all at once, just activate the plots to view them. With SOLIDWORKS Flow Simulation 2021, new columns provided in the summary table make it easier than ever to find the maximum value, and when it occurs.Ĭreating common plots to visualise results is now even more efficient by using the new ‘Create-Plots-From-Scene’ command. Goals are created to track these outputs, and by going to the history section of the goal plot, their values can be viewed throughout the duration of the study. This is ideal for mixing tasks and can be leveraged further to gain more insight into product performance.įor this thruster, we’re solving the torque and power requirements when it interacts with two separate fluids simultaneously. Now, in SOLIDWORKS Flow Simulation 2021, Rotating Regions can be combined with the ‘Free Surface’ feature. ‘Rotating Region’ is a powerful feature that’s used to simulate fluid driving motion in rotating components.

0 kommentar(er)

0 kommentar(er)